Before you can begin thinking about designing an aquaponic system, you must first identify the reason you are interested. The type and size of the system is determined by the end use of the system. The most common end uses are education, home food production or commercial production. It is possible, however, for a system to actually be all three of these uses, but serious compromises must occur in such a system. A school project system can fit on a desktop. A home food production system could be on a deck or in the backyard or even in a garage or small greenhouse. A commercial system will need at least one eighth acre.

But, a system that will provide a comfortable income for a family will need to be at least a quarter acre or more. Systems designed to provide food for large urban areas can be hundreds of acres.

2. Cost and Return on Investment

The cost of a school project or home food production system will be an amount that is determined by your budget. Usually the motivation for a home food production system is driven by a fascination with aquaponics or a passion for gardening and having a fun, year-round source of fresh produce and fish available. What ever your reason is for a home food system, it is usually not driven by getting a return on the investment.

When the aquaponic system is for commercial production you must do a very careful study of what it will cost to build the entire system and how long it will take to recoup the initial investment while making enough profit to continue the lifestyle you have become accustom to.

3. Build or Buy

With a little research it is easy to build a system for a school project or a small home food production system. As long as these systems aren’t stocked too heavily with fish, they will demonstrate the principles of aquaponics without much difficulty or maintenance.

When investing larger amounts of capital in a system that needs to return the investment, whether it is for commercial use or supplying food for home use in a serious way, it is wise to go with a proven design that will meet the expectations of the investor. If one is skilled in construction, the cost of a system can be re-duced by having the system designed and the components needed identified by someone experienced in the business and then doing as much of the construction as you are comfortable with.

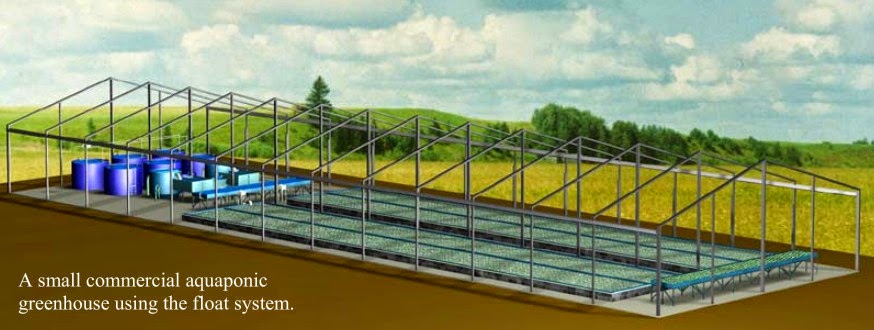

4. Greenhouse Design

While the small desktop systems can be set up in a home or classroom, there are very few locations that can justify having a system outdoors with no protection from the weather. In tropical locations where the temperature is agreeable, heavy rains and high winds can occur. A greenhouse cover can increase production and protect the crops from weather damage. In temperate regions, a structure that can be heated part of the year and cooled at other times is necessary. Building the correct greenhouse for your climate is essential to success. This is a component that is often overlooked. An improperly designed greenhouse often leads to crop stress and eventual failure at the attempt to do aquaponics.

5. Environmental Control

The environment surrounding an aquaponic system should include some ability to control some or all of the following: temperature, humidity, light levels and protection from rain, sleet, snow, wind and hail. The temperature of both the air and water may need to be controlled both upward and downward. In a serious home food production or commercial system, remote monitoring of these parameters and the ability to make adjustments from a remote location may be necessary. A back up source of power and water will also be necessary to assure success. Telephone lines and high speed internet connections make this quite easily achievable these days.

6. Biomass and Plant Count

The number one question asked is: How many fish to I need to grow x number of plants? While there are some general formulas to answer that question, it is better to identify your needs and work from there. If you know you want to harvest x number of plants per week to fill a certain market demand, it is easy to calculate the space you’ll need and the weight of fish you’ll need to supply that requirement. The key factor is the amount of food fed to the fish and having enough fish to eat that food in a certain period of time. The amount of waste generated by the fish is directly related to the amount of food fed to the fish and the amount of plants that you can grow.

%2Bdesign.jpg)

7. Grow Bed Design

The same choices available for hydroponic plant production are available for aquaponic systems. Floating rafts on shallow tanks of water are the most popular at present, but there is also a lot of interest in NFT (Nutrient Film Technique) channels. Determining the height of the plant grow bed is a consideration as well. The shallow tanks, often called float beds or raft tanks, are easier to work at if they are on tables, but supporting the weight requires a very strong support system. The NFT channels are easier to support at a comfortable working height.

An NFT system does not hold the large volume of water that a float system does because the NFT channels carry just a small trickle of water, whereas the float tanks are filled with water at a depth of about one foot. This affects the fish to plant ratios.

Many hobby growers use the media-filled bed system because it requires the least amount of equipment and is quite dependable. The disadvantage of a media-filled bed system is that the production on both the fish and plants is lower than that of float or NFT systems.

8. Moving the Water

How fast you circulate the water in the system and what method you use are issues related to system design . Two common methods of moving water are airlifts and water pumps. Large commercial systems most likely will use electric water pumps. Smaller systems can get by with airlifts. The advantage of airlifts is that they have much lower energy requirements, making it possible to use solar energy to power these systems.

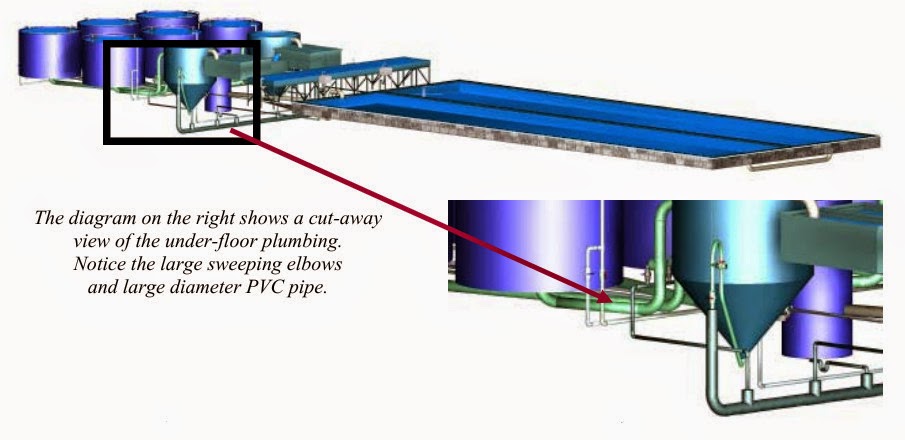

9. Pipe Size and Turns

It is important to use large enough PVC pipe, connectors and turns in any aquaponic system. Large diameter PVC pipe is very expensive and very often pipes get undersized in an effort to cut costs. Under-sizing pipe is a big mistake that you will pay for with clogs, improper flow rates and many other problems. When se-lecting elbows, choose the long sweeping elbows rather than sharp bends because the offer less resistance.

The actual cost of the greenhouse and aquaponic growing system can easily be calculated. Very often peo-ple think this is the only cost to starting a business in aquaponics. It is not unusual for the actual cost of the start up to exceed double the cost of the greenhouse and growing system.

One must also consider the cost of construction, the parts that don’t come with the “turnkey” package, support buildings, cold storage rooms, delivery vehicles, office equipment, business cards, brochures, advertis-ing, insurance, living expenses during the construction phase, the cost of borrowed money, taxes and maybe even the cost of the property to put the greenhouse on.

Be sure to consider all of the expenses of setting up an aquaponics business, not just the obvious equipment to grow the fish and plants.

credit to: John Pade

Inside our community you'll get access to a wide range of high quality, step-by-step Aquaponics System plans that are suitable for both small and large projects. You'll also get access to e-book guides, videos and a discussion forum. DOWNLOAD AQUAPONICS SYSTEM PLANS !